Research highlights

- Open-source tools were combined to analyse new on-farm pyrolysis heating systems.

- On-farm pyrolysis heating systems can achieve net negative emissions with biochar.

- Proper sizing of pyrolysis heating system is crucial to maximise biochar production.

- Biochar carbon sequestration came at an environmental cost, increased biomass use.

- Sustainable biomass provision and efficient biochar use are determinant factors.

Resources

Reference

Azzi ES, Karltun E, Sundberg C (2021) Small-scale biochar production on Swedish farms: A model for estimating potential, variability, and environmental performance. Journal of Cleaner Production 280:124873. DOI: 10.1016/j.jclepro.2020.124873

Presentations

The work was presented at a conference and several workshops. Download presentation slides below:

Model

The modelling was performed in python, using brightway2 and ficus. The files are available on GitHub at P2_farm_biochar.

Recordings

Watch a presentation of the article.

Want to read more?

Abstract

Several small-scale pyrolysis plants have been installed on Swedish farms and uptake is increasing in the Nordic countries. Pyrolysis plants convert biomass to biochar for agricultural applications and syngas for heating applications. These projects are driven by ambitions of achieving carbon dioxide removal, reducing environmental impacts, and improving farm finances and resilience.

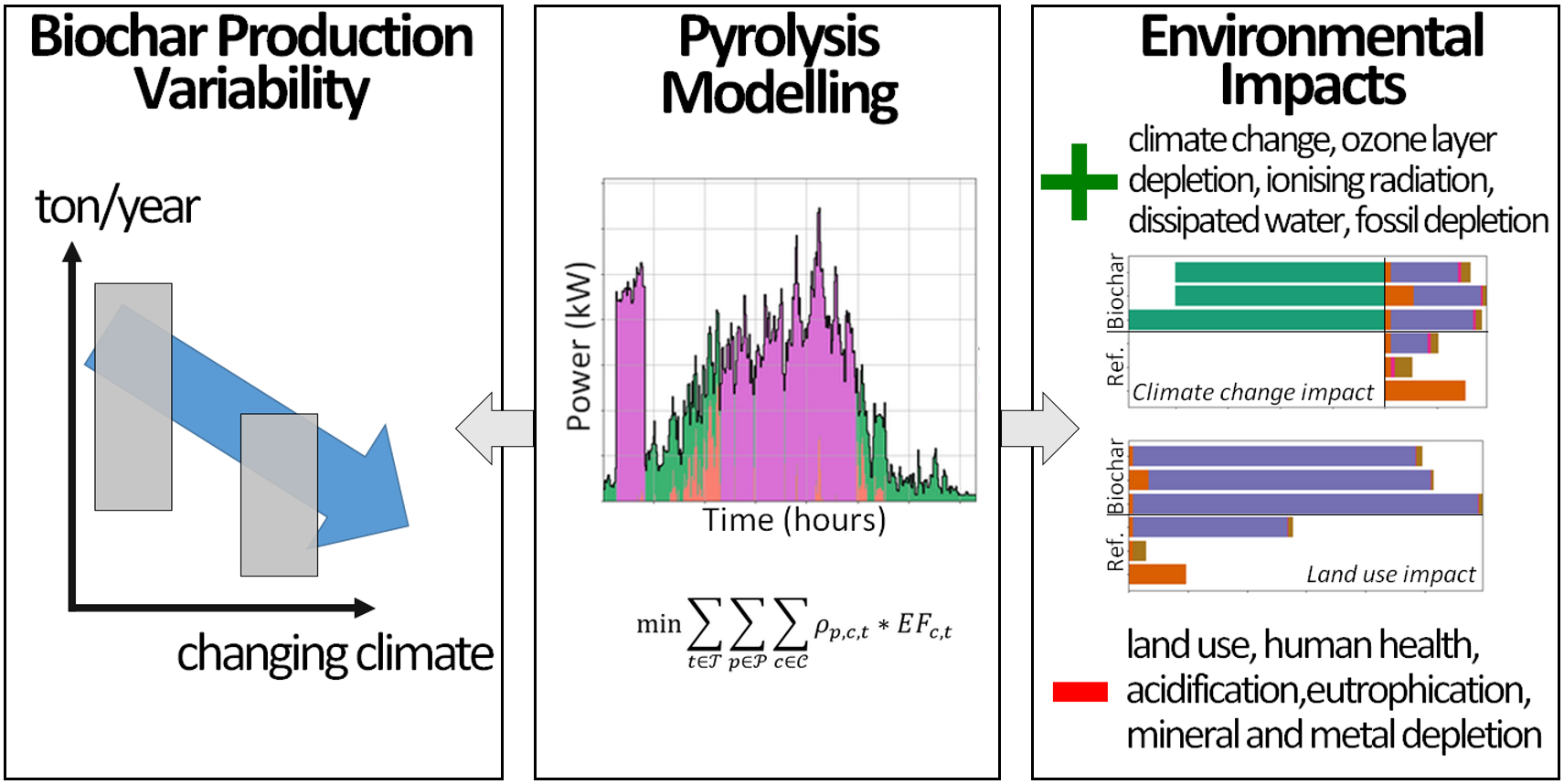

Before policy support for on-farm pyrolysis projects is implemented, a comprehensive environmental evaluation of these systems is needed. Here, a model was developed to jointly: (i) simulate operation of on-farm energy systems equipped with pyrolysis units; (ii) estimate biochar production potential and its variability under different energy demand situations and designs; and (iii) calculate life cycle environmental impacts. The model was applied to a case study farm in Sweden.

The farm’s heating system achieved net carbon dioxide removal through biochar carbon sequestration, but increased its impact in several other environmental categories, mainly due to increased biomass throughput. Proper dimensioning of heatconstrained systems is key to ensure optimal biochar production, as biochar production potential of the case farm was reduced under expected climate change in Sweden.

To improve the environmental footprint of future biochar systems, it is crucial that expected co-benefits from biochar use in agriculture are realised. The model developed here is available for application to other cases.

Frequently asked questions [under construction]

A compilation of comments and questions arising from disucssing this article. Don’t hesitate to contact us if you have questions.